Machined and Ground Finish Steel Plates Manufacturer

Machined and ground finish steel plates are used in various industries. They are produced by manufacturers who make sure that the steel plates meet specific requirements in terms of flatness, thickness, and surface finish. The machining process involves cutting and shaping the steel plates to the necessary dimensions. The grinding process follows, providing a smooth and uniform surface.

Manufacturing Process

- Material Selection: Manufacturers choose the appropriate grade of steel based on the

- Planned application.

- Cutting and Machining: The steel plates are cut to size and machined to achieve the required dimensions and tolerances.

- Grinding: The machined plates are ground to achieve a smooth surface finish and accurate thickness.

- Inspection: The final product is inspected to ensure it meets the required specifications.

Where Is Machined and Ground Finish Steel Plates Used?

1. Automotive Industry

A manufacturer provided machined and ground finish steel plates to an automotive company. The plates were used to produce components for vehicle engines. The company required plates with specific thickness and surface finish for accuracy assembly. The manufacturer delivered the plates according to the specifications. The automotive company reported improved performance in their production process due to the quality of the steel plates.

2. Aerospace Industry

An aerospace company needed machined and ground finish steel plates for aircraft parts. The manufacturer supplied plates that met the strict standards required in the aerospace industry. The plates were used in the production of landing gear machinery. The aerospace company was able to meet their production goals with the help of the steel plates provided by the manufacturer.

3. Heavy Machinery

A manufacturer of heavy machinery required machined and ground finish steel plates for their equipment. The plates were used in the construction of large-scale industrial machines. The steel plates needed to withstand high pressure and heavy loads. The manufacturer delivered the plates as per the specifications. The heavy machinery company reported enhanced durability and performance of their machines.

C45 Steel Machined and Ground Finish Steel Plate

C45 steel is a medium carbon steel grade widely used in various industries. It is known for its strength and good machinability, making it more suitable for manufacturing different machinery. C45 steel plates are used in the production of parts that require moderate strength and hardness.

C45 steel mainly consists of carbon and manganese, with small amounts of silicon, sulfur, and phosphorus. The carbon content in C45 steel is around 0.45%, which gives the steel its strength. The manganese content is around 0.60% to 0.90%, which helps improve the steel’s toughness and wear resistance. The other elements are present in smaller quantities and do not significantly affect the steel’s properties.

En8 Steel Machined and Ground Finish Steel Plate

EN8 steel is medium carbon steel widely used in engineering and manufacturing. It is known for its good strength and hardness, making it suitable for many industrial applications. EN8 steel plates are flat pieces of this steel cut and shaped for various uses. They are often chosen for components that require moderate strength and wear resistance.

EN8 steel primarily contains carbon and manganese, with small amounts of silicon, sulfur, and phosphorus. The carbon content in EN8 steel is about 0.40% to 0.45%, giving the steel its strength and hardness. Manganese, present at around 0.60% to 1.00%, improves the toughness and wear resistance of the steel. The other elements, like silicon, sulfur, and phosphorus, are present in smaller quantities and contribute to the steel’s overall properties.

P20 Machined and Ground Finish Steel Plate

P20 steel is commonly used in the manufacturing of plastic injection molds and die-casting tools. P20 steel plates are flat pieces of steel cut and prepared for various industrial. This steel is known for its good toughness, machinability, and uniform hardness, making it suitable for creating molds and tools that require accuracy and durability.

P20 steel is composed of several key elements, including carbon, chromium, manganese, and molybdenum. The carbon content is around 0.28% to 0.40%, providing a balance between strength and machinability. Chromium, present at approximately 1.40% to 2.00%, helps increase hardness and wear resistance. Manganese, at about 0.60% to 1.00%, improves toughness, while molybdenum, at around 0.30% to 0.60%, enhances the steel’s strength and harden ability. These elements work together to give P20 steel its desirable properties.

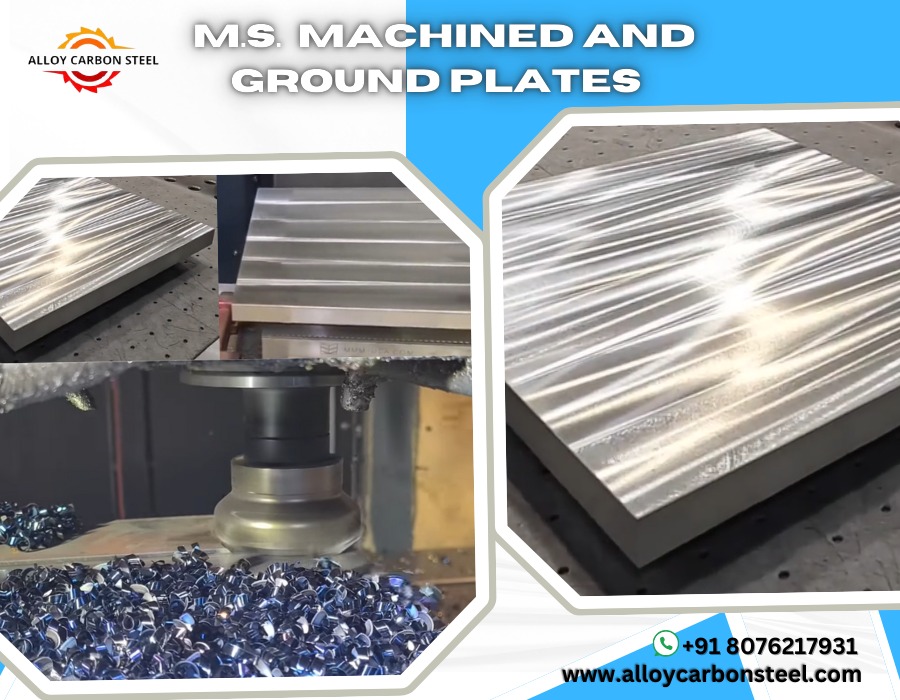

Mild Steel (M.S.) Machined and Ground Finish Steel Plate

Mild steel is a type of carbon steel that has low carbon element. It is one of the most common types of steel used in various industries due to its versatility and ease of use. Mild steel plates are flat pieces of this steel, cut to specific sizes and used in a wide range of applications. They are popular because they are easy to work with and can be used in many different ways.

Mild steel has low carbon content, typically around 0.05% to 0.25%. This low carbon content makes the steel more ductile, meaning it can be shaped and formed without breaking. Along with carbon, mild steel also contains small amounts of other elements such as manganese, silicon, and sometimes trace amounts of sulfur and phosphorus. These elements help improve the steel’s properties, making it suitable for various applications.

Why Choose Alloy Carbon Steel?

Choosing, Alloy Carbon Steel for machined and ground finish steel plates means selecting a partner with experience and reliability. Located in Delhi, Alloy Carbon Steel specializes in providing high-quality steel plates customized to meet specific project needs.

Their focus on accuracy machining and ground finishes ensures that each plate is crafted to exact dimensions, ready for direct use in demanding applications. This attention to detail reduces the need for further processing, saving time and resources.

Alloy Carbon Steel’s range of materials includes options suitable for various industries, from tooling to heavy machinery. Their ability to deliver on time and meet tight deadlines makes them a preferred choice for businesses that cannot afford delays.

The team at Alloy Carbon Steel is committed to understanding the unique requirements of each project, offering support and solutions that align with specific goals. This commitment to service means clients can rely on consistent quality and performance from their steel plates.

Alloy Carbon Steel, located at 693 Saini Vihar, Mundka, Delhi 110041, is a trusted supplier of premium quality heavy metals. Specializing in Plastic Mould Steel, Carbon Steel, Die Steel, High Speed Steel, and Alloy Carbon Steel, they cater to industries that demand high-performance materials.

For further details:

Company: Alloy Carbon Steel

Phone no.: 8076217931

Mail I’d: sumit_garg_1@yahoo.co.in

Website: alloycarbonsteel.com

Address: 693 Saini Vihar, Mundka, Delhi, India 110041