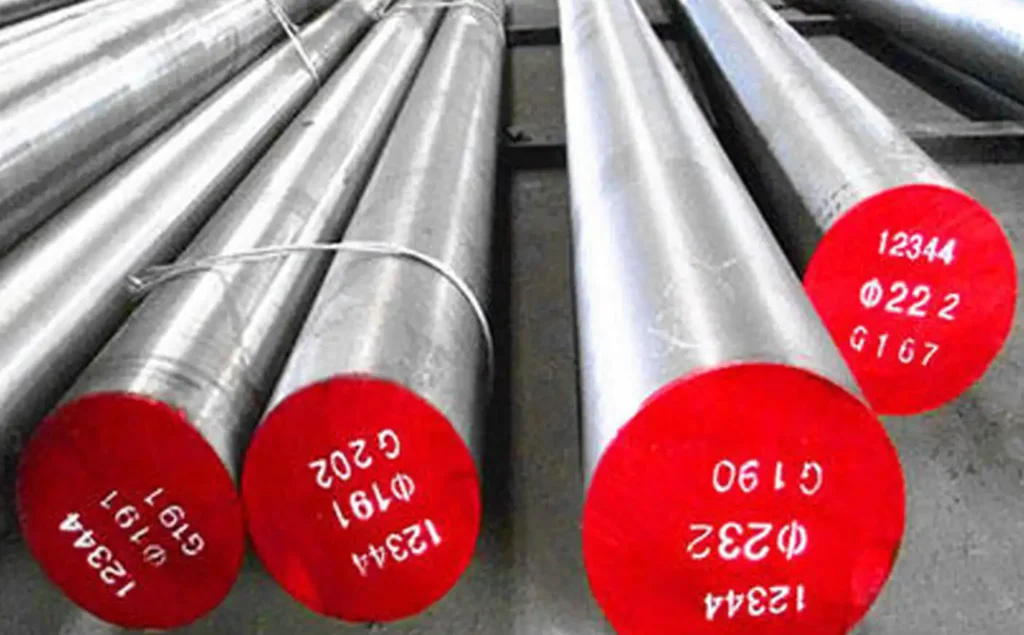

M2 tungsten-molybdenum High Speed Steel

M2 tungsten-molybdenum High Speed Steel

M2 metal is a widespread motive molybdenum-type high-speed metal displaying well-balanced durability, put on-resistance and pink hardness residences. This grade is normally used in bloodless work punches and dies and slicing programs regarding excessive-pace and light cuts. M2 high-speed steel is through a long way the maximum famous high-speed metal changing T1 in most programs due to its advanced houses which include its bending strength, toughness and thermo-plasticity—all of which might be better than T1 with the aid of 50%.

Characteristic properties of M2 steel grades:-

- High wear resistance.

- High working hardness.

- Excellent toughness.

- High retention of hardness and red hardness.

EQUIVALENT GRADES OF M2 HIGH SPEED STEEL:

| DIN 1.3343 | AFNOR 06-05-04-02 | JIS SKH9 | SS 2722 |

| FED QQ-T-590 | UNI KU | B.S. BM 2 | ASTM A597 (CM-2) |

| SAE J437 | ASTM A600 | SAE J438 | UNS T11302 |

Chemical Composition of M2 High Speed Steel:

| Element | Content (%) |

| C | 0.78-1.05 |

| Mn | 0.15-0.40 |

| Si | 0.20-0.45 |

| Cr | 0.20-0.45 |

| Ni | 0.3 |

| Mo | 4.50-5.50 |

| W | 5.50-6.75 |

| V | 1.75-2.20 |

| Cu | 0.25 |

| P | 0.03 |

| S | 0.03 |

Physical Properties of M2 High Speed Steel:

| Density | Specific Gravity | Modulus of Elasticity | Machinability |

| 0.294 lb/in3 (8138 kg/m3) | 8.14 | 30 x 106 psi (207GPa) | 50-60% of a 1% carbon steel |

HEAT TREATMENT OF M2 TOOL STEEL:

M2 steels are tempered at 565.5°C (1050°F) to obtain hardness from 60 to 65 HRC.

| ANNEALING | PREHEAT | AUSTENITIZING | QUENCH | TEMPERING |

| Temp | Temp( °F) | Temp( °F) | Temp( °F) | Temp( °F) |

| 1550/1600 | 1500/1550 | 2175/2225 | SALT/OIL | 1025/1050 |

Applications of M2 Tool Steel:

The main use of excessive-pace steels remains within the manufacture of various slicing equipment. Typical programs for M2 high speed steel are twist drills, reamers, broaching tools, taps, milling tools, steel saws. M2 is appropriate for bloodless forming gear consisting of extrusion rams and dies, additionally broadly used in all types of slicing gear, knife and punches and die programs, plastic moulds with increased put on resistance and screws.

TYPES OF OTHER GRADES AVAILABLE:

C45, EN8, EN9, EN19, EN24, EN31, EN36C, EN41B, EN47, EN353, IS2062, 42Crmo4, HCHCR, OHNS, D2, D3, H-11, H-13,M2, M35, M42, M48,1.2714, SKD-11, P20, P20+S, P20+Ni, P20+Ni+HH, SAE 4140, SAE4340, SAE 8620, 16MNCR5, 20MNCR5, C35, C40, C50, C60, CK45, 40C8, 45C8, 55C8, C55MN75, SAE 52100, S40C,S355J2G3.

CITIES IN WHICH WE ARE DEALING:

Uttar Pradesh:

Kanpur,Lucknow,Ghaziabad,Agra,Meerut,Varanasi,Prayagraj,Bareilly,Aligarh,Moradabad,Saharanpur,Gorakhpur,Noida, greater Noida, udham nagar,Firozabad,Jhansi,Muzaffarnagar,Mathura,Ayodhya,Rampur,Shahjahanpur,FarrukhabadFategarh,Budaun,Maunath,Bhanjan,Hapur,Etawah,Mirzapur,Vindhyachal,Bulandshahr,Sambhal,Amroha,Hardoi,Fatehpur,Raebareli,Orai,Sitapur,Bahraich,Modinagar,Unnao,Jaunpur,Lakhimpur,Hathras,Banda,Pilibhit,Barabanki,Khurja,Gonda,Mainpuri,Lalitpur,Etah,Deoria,Badaun,Ghazipur,Sultanpur,Azamgarh,Bijnor,Sahaswan,Basti,Chandausi,Akbarpur,Ballia,Tanda,Shikohabad,Shamli,Awagarh,Kasganj.

Rajasthan:

Jaipur, Jodhpur, Kota, Bikaner ,Bhiwadi ,Ajmer ,Udaipur ,Bhilwara ,Alwar ,Bharatpur,bharan ,Sri Ganganagar ,Sikar ,Pali ,Tonk ,Kishangarh ,Beawar ,Hanumangarh ,Dhaulpur ,Gangapur City, Sawai Madhopur ,Churu ,Jhunjhunu ,Baran ,Chittaurgarh ,Makrana ,Nagaur ,Banswara ,Dungarpur, pratapgarh

Haryana:

Faridabad (New Township) , Gurgaon , Panipat, Yamunanagar, Rohtak, Hisar, Karnal, Sonipat, Panchkula (Urban Estate), Ambala Sadar, Bhiwani, Ambala, Sirsa, Bahadurgarh, Jind, Thanesar, Kaithal, Rewari, Palwal, Hansi, Narnaul, Fatehabad, Gohana, Tohana, Narwana.